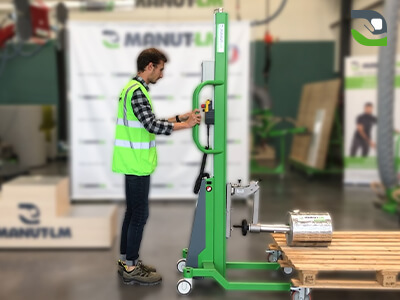

GM-Spools | Spool Lifting Trolley

Lifting trolleys and StackersGM-Coils – Coil stacker trolley from 80 to 600 kg

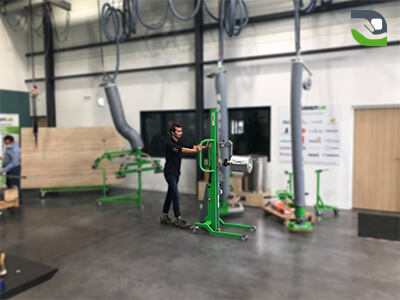

The GM-Spools handling stackers are designed to eliminate physical strain and to make the operators autonomous in Spool-lifting operations.

Thanks to a wide range of made-to- measure tools, GM-Spools adapts to all Spool formats up to 600 kg and to all types of handling.

Horizontal or vertical pick-up and drop-off at the end of a production line or to feed packaging machines: GM-Spools adapts to all environments.

Download the documentation

- Lifting of Spools up to 600 kg

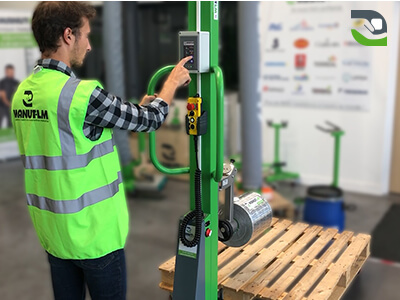

- Interchangeable gripping tools in a matter of seconds to adapt to different formats

- Easy lifting, tilting and turning of Spools

Job offers

Job offers