Vacuum-tube handling – What is it all about?

The manual handling of loads is a common activity in all the companies involved in the production of goods, trading or services.

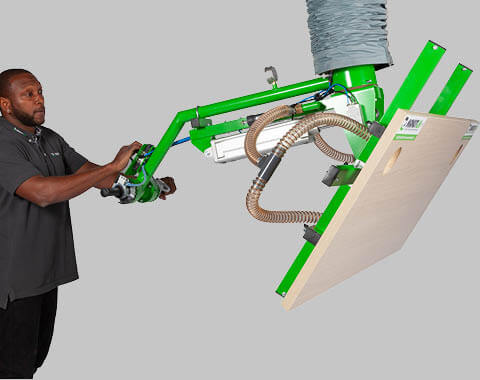

In order to reduce the strain of employees, it is necessary to find solutions formanual handling, whether it is for lifting heavy loads or for tasks where handling is repetitive.

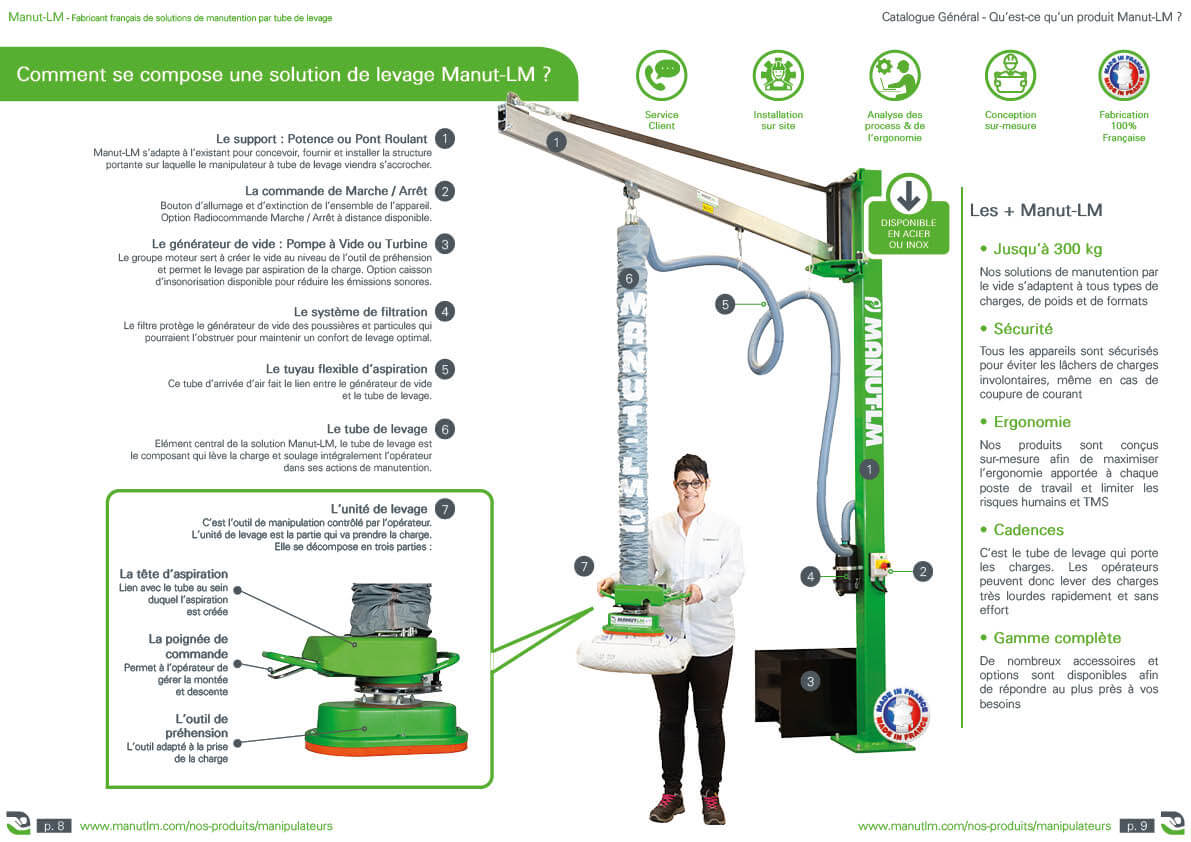

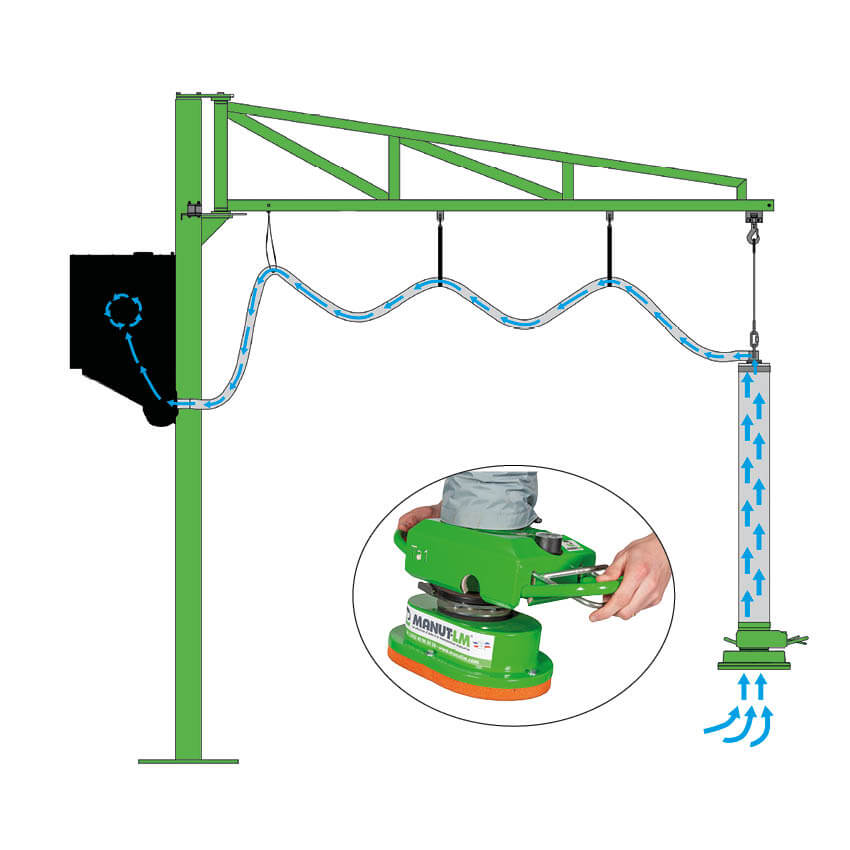

The vacuum-tube handling system is a technology that allows to carry effortlessly various loads thanks to a suction system. The weight is then removed for the operators.

- A vacuum generator creates a suction in a tube,

- The air intake allows the loads to be picked up with a gripping tool,

- The lifting tube compresses when obstructed by the load, which lifts the load

- A control handle allows to control the orientation of the device and the lifting/lowering of the load

This technology is widely used in industrial and logistics environments, in particular because it integrates perfectly into all types of environments. It eliminates the risk of musculoskeletal disorders or MSDs, particularly in areas where physical work is strenuous.

Job offers

Job offers